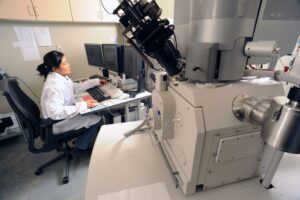

Innovation Laboratory

Current research projects include experiments related to heat transfer. Heat transfer equipment includes:

- Thermal hydraulic loop

- Pressure resistance welder

The lab space also includes an electronics lab facility. Equipment includes:

- Antistatic flooring

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum.

Research

Temperature Effects on Surface Wettability and Critical Heat Flux Prediction of Accident Tolerant Fuel (ATF)

Ramè-Hart Model 250 Goniometer-Tensiometer

Modeling and Experimental Validation of Latent Heat Thermal Energy Storage System

Research: The goal is to investigate the temperature effects on the wettability measurements for Accident Tolerant Fuel (ATF) claddings. The project will utilize the existing surface characterization facility, Goniometer-Tensiometer.

Benefits: The wettability change is used to predict the thermal-hydraulic safety limit, Critical Heat Flux (CHF), at elevated temperatures to provide more representative data to the ATF material and thermal-hydraulics researchers.

Research: The Catalysis & Transient Kinetics Laboratory contains a goniometer-tensiometer that provides a broad spectrum of measurements, including static contact angle, surface energy, surface tension, and interfacial tension.

With accessories upgrades, the unit can provide additional measures, including dynamic contact angle, and surface dilatational elasticity and viscosity. The Goniometer-Tensiometer unit includes a fiber-optic illuminator, a 3-axis specimen stage with leveling, U4 Series 520 frames/second super-speed digital camera, a micro-syringe fixture for manual dispensing, and a PC with the analytical software and LCD.

Benefits: Improving wettability and surface adhesion, which has applications in materials science, nuclear reactors, heat pipes, semiconductors, filtration technology, printing, and textiles. The equipment improves predictions related to critical heat flux in steam generators, heat exchangers, and light water reactors.

Research: The Latent Heat Thermal Energy Storage project is aimed at developing validated models for a phase change material (PCM)-based thermal battery in order to collaborate with ongoing modeling efforts at Idaho National Laboratory. The developed models will be analyzed and optimized in RAVEN to evaluate the economic potential and advantages of coupling thermal energy storage to existing clear energy generating sources. Additional studies are being conducted to study the enhancement of the effective thermal conductivity of PCMs, brought about by conductive additives.

Benefits: Accelerate the development of Nuclear-Renewable Hybrid Energy Systems.

Lab News

Advanced Visualization Lab Publishes 15-Year Study

Researchers in the CAES Applied Visualization Lab (AVL) recently published...

Read MoreIdaho National Laboratory and Colorado School of Mines expand research partnership

Idaho National Laboratory (INL) and the Colorado School of Mines...

Read MoreCAES hosts VIPs from Ohio State University

CAES hosted a great visit by Ohio State University’s Center...

Read MoreMaCS Seed Grant Program Awards up to $5K each

The Center for Advanced Energy Studies (CAES) is pleased to...

Read More