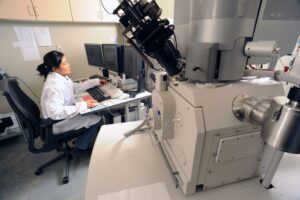

Advanced Materials and Characterization Laboratory

The state-of-the-art equipment in this highly utilized lab offers a variety of sample preparation capabilities for radiological and non-radiological materials.

Closely linked to the Microscopy and Characterization Suite, the Advanced Materials Laboratory (AML) offers a broad range of sample preparation capabilities in the areas including processing, structural analysis, and properties determination.

Specifically, AML provides:

- Radiological and non-radiological materials processing (sintering, welding, casting, machining, deposition)

- Determination of materials structure of samples (atomic, nano, and mesostructures)

- Analysis of material’s properties (strength, toughness, creep, slow crack growth, Moduli, diffusion, thermal conductivity, thermal expansion, corrosion resistance, etc.)

- New materials that can withstand higher pressure levels and temperatures are needed to boost power plant efficiency, so are materials that can extend the life of the nation’s nuclear plants

- CAES researchers are creating and testing new materials to ensure they can withstand extreme environments. They also are experimenting with new welding techniques to ensure these materials can be used in a commercial setting

Research

Spark Plasma Sintering (SPS)

Crack Creep Testing

Resistance Welding

Research: The Advanced Materials Laboratory contains a Spark Plasma Sintering system, which allows researchers to combine metal and ceramic powders to produce new materials. There are only a handful of these unique systems in the U.S.

SPS produces unique materials engineered for properties that include high wear resistance, high heat strength, high magnetism, and functional porosity or density.

Benefits: Creating advanced materials for weapons, optics, tooling, and nuclear energy

Research: Crack Creep Testing is a method for determining how cracks form and how cracks creep through metals.

Benefits:

- Supports life extension of U.S. Light Water Reactor Fleet

- Ensures integrity and safety

- Ensures components, materials and products are fit-for-purpose

- Ensures compliance with NRC standards

Research: Resistance welding fuses metals heated by electrical resistance. This experiment welds oxide-dispersion strengthened alloy (ODS) samples.

- ODS alloys are used in nuclear applications and for high temperature turbine blades and heat exchanger tubing

- ODS materials clad space craft to protect the passengers during re-entry into the atmosphere

- Noble metal alloy ODS materials are used in glass production

Benefits: ODS Alloys lose strength when welded by conventional means — this research may expand the use of these important alloys in energy production and in other industrial applications.

Lab News

Advanced Visualization Lab Publishes 15-Year Study

Researchers in the CAES Applied Visualization Lab (AVL) recently published a study sharing experiences and lessons learned during the lab’s...

Read MoreIdaho National Laboratory and Colorado School of Mines expand research partnership

Idaho National Laboratory (INL) and the Colorado School of Mines (CSM) have signed a memorandum of understanding to expand their...

Read MoreCAES hosts VIPs from Ohio State University

CAES hosted a great visit by Ohio State University’s Center for Design and Manufacturing Excellence this week. Ed Herderick, the...

Read MoreMaCS Seed Grant Program Awards up to $5K each

The Center for Advanced Energy Studies (CAES) is pleased to announce a MaCS Seed Grant Program. With support from Boise...

Read More